Low water pressure can turn simple daily tasks into frustrating experiences. When your push-pull valve isn’t delivering the water flow you need, it’s time to investigate the root cause. Professional plumbing solutions from companies like Think House Creative can help homeowners understand and resolve these common water pressure issues effectively.

Push-pull valves are essential components in modern plumbing systems. These mechanisms control water flow by simply pushing or pulling the valve handle. However, when water pressure drops significantly, the problem often lies within the valve mechanism itself or the surrounding plumbing infrastructure.

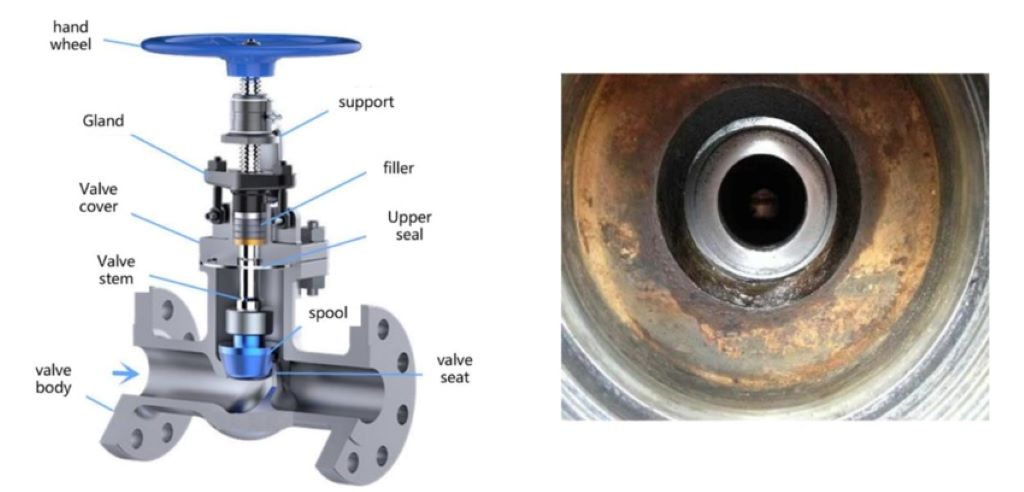

Understanding how your push and pull water shut off valve functions is crucial for effective troubleshooting. These valves contain internal components that can become damaged, clogged, or worn over time. Additionally, external factors like mineral buildup, debris accumulation, or system-wide pressure issues can impact performance.

Common Causes of Low Water Pressure in Push Pull Valves

Several factors contribute to reduced water pressure in push-pull valve systems. Identifying the specific cause helps determine the most appropriate solution for your situation.

Mineral deposits represent one of the most frequent culprits. Hard water contains calcium, magnesium, and other minerals that gradually accumulate inside valve components. These deposits restrict water flow and create pressure bottlenecks throughout the system.

Debris and sediment can also obstruct valve openings. Small particles from aging pipes, construction work, or municipal water system maintenance sometimes lodge within valve mechanisms. This obstruction reduces the effective opening size and limits water flow capacity.

Worn or damaged valve seals create another common problem. Rubber gaskets and O-rings deteriorate over time, especially when exposed to harsh water conditions or extreme temperatures. Damaged seals allow water to bypass intended flow paths, reducing overall pressure.

Step-by-Step Troubleshooting Process

Begin your troubleshooting process by checking the water pressure throughout your home. Turn on multiple faucets simultaneously to determine whether the pressure issue affects only the push-pull valve or the entire plumbing system.

If other fixtures maintain normal pressure, focus your attention on the specific valve experiencing problems. Start by examining the valve handle and surrounding connections for visible signs of damage, corrosion, or loose fittings.

Next, carefully remove the valve handle according to manufacturer instructions. Most push and pull water shut off valve systems have removable components that allow access to internal mechanisms. Take photos before disassembly to ensure proper reassembly later.

Inspect the valve stem, packing, and internal components for mineral buildup, corrosion, or physical damage. Clean all accessible parts using appropriate cleaning solutions and soft brushes to remove deposits without damaging delicate components.

Cleaning and Maintenance Techniques

Proper cleaning techniques can restore optimal function to your push-pull valve system. Use white vinegar or specialized lime-scale removal products to dissolve mineral deposits effectively. Soak removable components in cleaning solution for several hours or overnight for stubborn buildup.

Gentle scrubbing with an old toothbrush helps remove loose debris without scratching valve surfaces. Pay special attention to valve seats, where the moving components create seals during operation. These areas typically accumulate the most deposits and require thorough cleaning.

Replace worn or damaged seals, gaskets, and O-rings during the cleaning process. These inexpensive components often solve pressure problems when replaced with properly sized parts. Consult your valve documentation or take old parts to hardware stores for accurate matching.

After cleaning and replacing worn components, reassemble the valve carefully. Apply appropriate thread sealant or plumber’s tape to threaded connections to prevent leaks. Avoid overtightening, which can damage components or create new problems.

When to Call Professional Plumbers

Some push-pull valve issues require professional intervention. Complex internal damage, such as cracked valve bodies or severely corroded components, often necessitates complete valve replacement by experienced plumbers.

If your troubleshooting efforts don’t improve water pressure, underlying plumbing problems may be responsible. Issues like clogged supply lines, faulty pressure regulators, or municipal water system problems require professional diagnosis and repair.

Safety considerations also warrant professional assistance. Valves controlling gas lines, main water supplies, or complex multi-zone systems should only be serviced by licensed professionals with appropriate tools and expertise.

Additionally, if you’re uncomfortable performing any troubleshooting steps or lack necessary tools, professional plumbers can efficiently diagnose and resolve push and pull water shut off valve problems while ensuring proper safety protocols.

Preventive Maintenance for Long-Term Performance

Regular maintenance prevents many common push-pull valve problems. Schedule annual inspections of all valve systems to identify potential issues before they cause significant water pressure reduction.

Water quality improvement through filtration or softening systems reduces mineral accumulation in valve components. These systems remove harmful minerals and sediments that contribute to valve deterioration and performance problems.

Exercise your valves periodically by operating them through full open and closed cycles. This movement prevents components from seizing due to mineral buildup and helps identify problems while they’re still manageable.

Keep replacement parts readily available for your specific valve models. Common items like O-rings, gaskets, and packing materials allow for quick repairs when problems arise, minimizing disruption to your daily routines.

Understanding Water Pressure Systems

Residential water pressure typically ranges from 40 to 60 pounds per square inch (PSI). Pressure below this range indicates system problems that may affect push-pull valve performance throughout your home.

Pressure regulators control incoming water pressure from municipal supplies. These devices can malfunction or require adjustment, creating system-wide pressure issues that impact all fixtures and valves.

Elevation changes within your home also affect water pressure. Upper floors naturally experience lower pressure due to gravity, making push-pull valve problems more noticeable in these locations.

Peak usage periods can temporarily reduce water pressure when multiple fixtures operate simultaneously. However, consistently low pressure during normal usage periods indicates problems requiring attention.

Replacement Considerations

When cleaning and minor repairs don’t restore adequate water pressure, valve replacement becomes necessary. Modern push and pull water shut off valve designs offer improved durability and performance compared to older models.

Consider upgrading to valves with ceramic disc cartridges, which resist mineral buildup and provide longer service life than traditional rubber-sealed designs. These premium components justify their higher cost through reduced maintenance requirements and superior performance.

Proper sizing ensures optimal pressure and flow rates for your specific applications. Consult plumbing professionals or valve manufacturers to select appropriately sized replacements that match your system requirements.

Installation quality significantly impacts valve performance and longevity. Even high-quality valves can experience premature problems when installed incorrectly, making professional installation a worthwhile investment for complex systems.

Conclusion

Low water pressure in push-pull valves typically results from mineral buildup, debris accumulation, or worn components that restrict water flow. Systematic troubleshooting involving inspection, cleaning, and component replacement often restores normal pressure levels.

Regular maintenance prevents many common valve problems and extends component life significantly. Simple steps like periodic operation, water quality improvement, and annual inspections help maintain optimal performance.

When DIY troubleshooting doesn’t solve pressure problems, professional plumbers can diagnose complex issues and perform necessary repairs safely. Don’t hesitate to seek expert assistance for safety-critical systems or when you’re unsure about proper procedures.

Frequently Asked Questions

Why is my push-pull valve suddenly losing water pressure? Sudden pressure loss usually indicates debris obstruction, damaged seals, or mineral buildup restricting water flow through valve components.

How often should I clean my push and pull water shut off valve? Clean valves annually in hard water areas, or every two years in areas with softer water to prevent mineral accumulation and maintain optimal performance.

Can I use regular household cleaners on valve components? Use only plumbing-specific cleaners or white vinegar to avoid damaging rubber seals and metal components with harsh chemicals.

When should I replace rather than repair my push-pull valve? Replace valves with cracked bodies, severely corroded components, or those requiring frequent repairs to ensure reliable long-term performance.

What tools do I need for basic push-pull valve troubleshooting? Basic troubleshooting requires adjustable wrenches, screwdrivers, cleaning brushes, and appropriate replacement seals for your specific valve model.

Read More:

How to Restore Shine: Effective Ways to Remove Hard Water Stains